Mining of tanzanite

With an established direct-to-mine relationship, Shimansky sources top quality certified tanzanite direct from the Maasai tribe in Tanzania, contributing to their sustainability and affording a unique opportunity to select the latest tanzanite mined. These beautiful, top quality gems are transformed into stunning Shimansky tanzanite jewellery creations, forming part of the Ayanda Queen of Tanzanite jewellery collection.

Since the discovery of tanzanite in 1967, it is estimated that two million carats of tanzanite were mined in Tanzania before the Tanzanian government nationalised the mines.

Only two kilometres wide and four kilometres long, the tanzanite mining area was divided into four sections by the Tanzanian government in 1990. These sections are known as Blocks A, B, C and D and have been allotted to different mining groups. The A-Block and C-Block are reserved for foreign investment and large operators, while B and D can be mined by locals.

Tanzanite is found in sausage-shaped formations, called boudins. Boudins are pegmatitic veins that have become stressed and have broken into smaller pieces. Tanzanite stones are found in small pockets inside the boudins. Not every boudin will produce tanzanite, and many that do, contain low-grade material not useful for jewellery.

Initially, tanzanite was easily collected from the surface, but scavenging mining didn’t last long and pits and tunnels quickly took preference. Geological testing has shown that tanzanite layers exist down to 200 meters below the ground. As mining levels drop deeper, increasingly sophisticated infrastructure is required to access the tanzanite. World-class infrastructure is put in place to secure the shafts, provide air supply and ventilation, watering and dewatering, to ensure the safety of the mine workers, and ensure that the tanzanite can be extracted safely and productively.

Processing and sorting takes place on-site. Rough tanzanite is sorted both manually and using a fully automated optical sorting/primary grading system - a world first in the coloured gemstone industry. There are various steps in the sorting process.

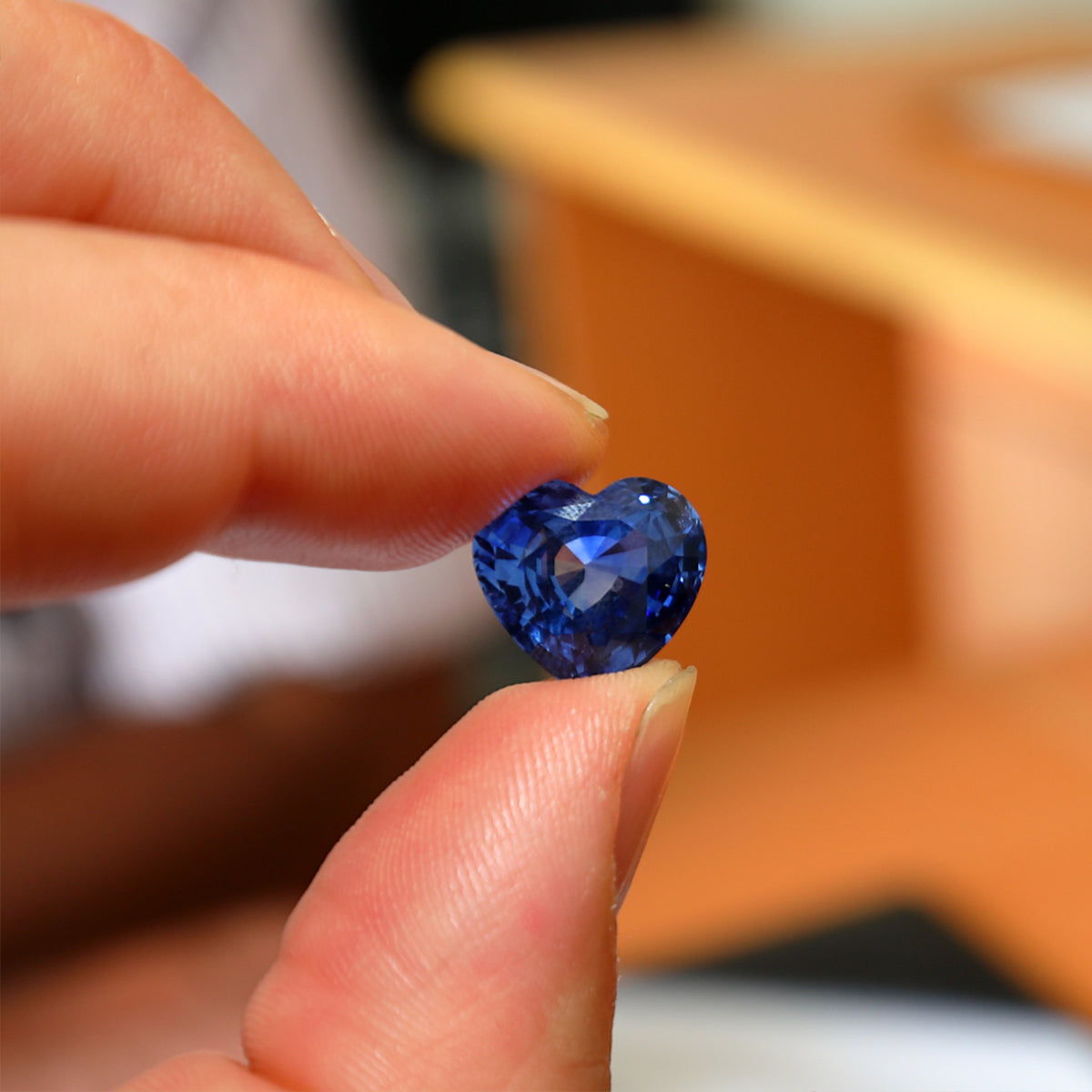

The tanzanite is then pushed against a lap (a spinning wheel) to polish the stone. Polishing gives the stone its final facets and it is during this stage that the gem comes to life. The process requires a huge amount of skill and concentration, and it is this part of the process where the stone is given its grandeur. The gem is meticulously checked by the cutter after each facet has been polished; he inspects each facet closely before moving onto the next one. After being polished, the tanzanite is ready to be sent to the Tanzanite International grading facility, where its colour, clarity, cut and carat weight will be graded. Once the grading is complete, the gem will either be sold as a loose stone, or it will be set in a beautiful jewellery creation.

Tanzanite is a unique gem, and requires experience, skill and attention to detail in the cutting and polishing processes. To achieve the optimum cut, the cutter must give the gem his undivided attention, and as a result, it can take days to cut and polish a single stone. The result, however, is worth the effort. Tanzanite jewellery is not only a great investment, but is absolutely beautiful to wear. When buying tanzanite in South Africa, select a stone from a reputable jeweler that has been cut and polished to maximise its beauty and reveal its true potential.

Tanzanite is found in sausage-shaped formations, called boudins. Boudins are pegmatitic veins that have become stressed and have broken into smaller pieces. Tanzanite stones are found in small pockets inside the boudins. Not every boudin will produce tanzanite, and many that do, contain low-grade material not useful for jewellery.

Firstly, the gems are picked from the shaft, after which they are taken to the sorting house where they are cleaned and weighed. Unwanted materials (ie. non-gem matter) are removed from the gems, and then the cobbing process begins. The gems are cobbed and graded so that they can be divided into various groups. Gems of good quality are taken away for carat, clarity and colour grading, while others are taken away to be sold as they are, and the off-cuts or “waste” are collected to be sold locally. Once all the grading and sizing procedures have taken place, the gems are packed and ready to be sold.

Around 70 000 people are supported and employed by the tanzanite mining, cutting and trading industry, worldwide. Buying tanzanite in South Africa and other countries, from a reputable jeweller, supports the Tanzanian economy, and allows buyers to invest in something truly spectacular – a gem so precious and rare, that even the most striking sapphires struggle to compete with its beauty.

The true value of a Shimansky jewellery creation is only realised when it is worn by the person it is meant for.

Featured collection

TANZANITE

0.27 TCW | Round | Classic | 14K White Gold

0.06 Carat | Round | Africa Design | 18K Yellow Gold

0.08 TCW | Round | Thread Dangling | 14K Yellow Gold

2.5 Carat | Round | Halo | 14K White Gold